2000 Custom Built Devonport Challenge 72

Yacht price :

Overview

2000 Custom Built Devonport Challenge 72 Sailboat For Sale in Ensenada, Mexico.

~!~! NOT FOR SALE IN US WATERS OR TO US CITIZENS !~!~

IRONBARQUE has been consistently maintained and updated Thorough refit in 2016.

With their solid heavy gauge steel hulls designed to withstand the worst that the Southern Ocean could throw at them, and their stainless steel decks, the Challenge 72 is an iconic, and unbreakable yacht. In this ownership, she has been updated for family cruising and has sailed far with her current family and has done so in safety and comfort. She has been altered to meet the needs of a growing family, but the fundamentals of her design remain and if needed, she would be easily re-coded to MCA Category 0. She is ready for more oceans.

ADDITIONAL PHOTOS AVAILABLE UPON REQUEST

~Vessel is located in Ensenada, Mexico~

Specifications

Basic Information

- Manufacturer:

- Custom Built

- Model:

- Devonport Challenge 72

- Year:

- 2000

- Category:

- Sail

- Condition:

- Used

- Location:

- Ensenada, Baja Norte, MX

- Available for sale in U.S. waters:

- No

- Vessel Name:

- Ironbarque

- Boat Type:

- Racer and Cruiser

- Hull Material:

- Steel

- Hull Type:

- Monohull

- Hull Color:

- Designer:

- Flag of Registry:

Dimensions & Weight

- Length:

- 72 ft - 21.95 meter

- LOA:

- 72 ft 2 in - 22 meter

- Beam:

- 18 ft - 5.49 meter

- Draft - max:

- 10 ft - 3.05 meter

- Bridge Clearance:

- -

- Dry Weight:

- 83600 lbs

Engine

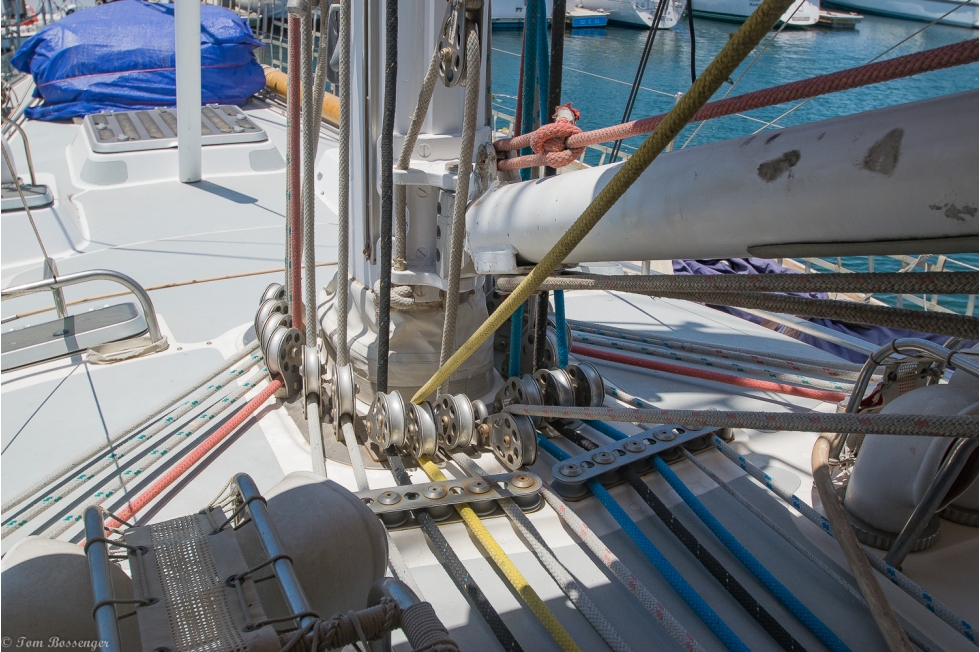

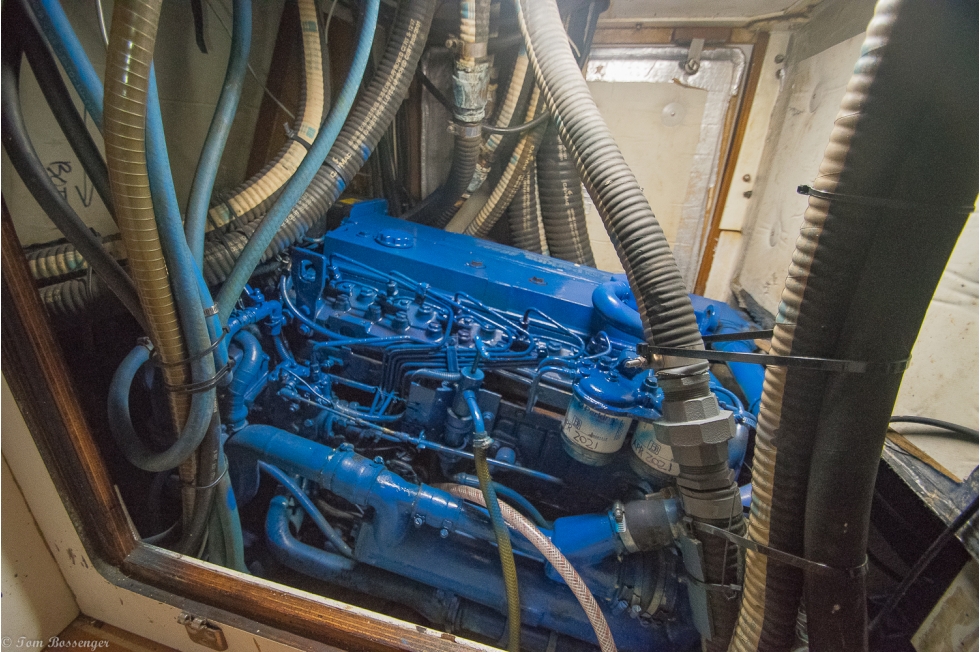

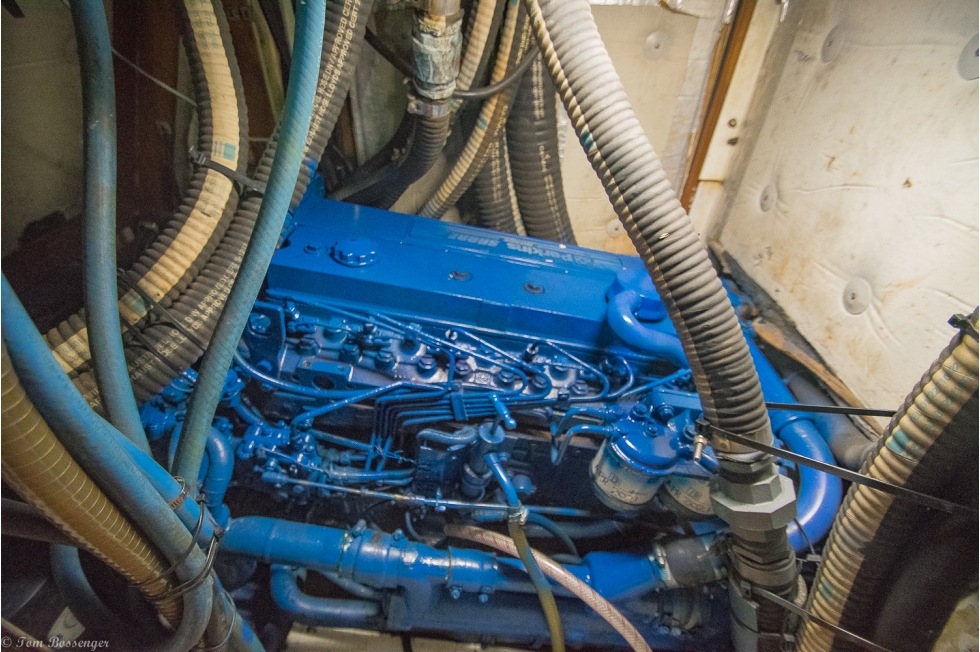

- Make:

- Perkins

- Model:

- M130C

- Engine(s):

- 1

- Hours:

- -

- Cruise Speed:

- -

- Range:

- -

- Joystick Control:

- No

- Engine Type:

- Drive Type:

- Direct Drive

- Fuel Type:

- Horsepower:

- 125 (Individual), 125 (combined)

- Max Speed:

- -

Tank Capacities

- Fuel Tank:

- 475 gallons - 1 tank(s)

- Fresh Water Tank:

- 390 gallons - 1 tank(s)

- Holding Tank:

- -

Accommodations

- Total Cabins:

- 4

- Total Berths:

- -

- Total Sleeps:

- -

- Total Heads:

- 2

- Captains Cabin:

- No

- Crew Cabins:

- -

- Crew Berths:

- -

- Crew Sleeps:

- -

- Crew Heads:

- -

Descriptions

Descriptions

Overview

General Description:

The Challenge 72' Class yachts were designed for The Challenge Business by an appointed design team, specifically to race around the world “the wrong way”. The design brief called for exceptionally strong, seaworthy, fast, attractive, modern, steel yachts that were able to sail to windward across the Southern Ocean in relative comfort.

Safety was paramount both in terms of structural strength and crew safety. Because of the One Design nature of the race, the design was not influenced or distorted by any rating rule and a sensible displacement was specified. Other important design considerations include, ease of access to the structure, equipment, systems, wiring and fittings for maintenance and inspections both at sea and in harbour. Every piece of equipment had to be robust enough to survive a race around the world with minimum maintenance.

Devonport Yachts (DML) were chosen to build the fleet to Bureau Veritas highest notation. The construction method allows relatively simple and cost effective alterations to the interior layout.

IRONBARQUE was sold to her current owners by the Challenge Business and has been sailed extensively privately. The vessel underwent refit to make her more easily sailed by a family crew and great attention was paid to maintaining and building upon her safety equipment.

IRONBARQUE was sailed privately with six aboard (two adults and four children). The use of crew might lift that number to eight. Three new Solas A six man life rafts were purchased in 2015 (per MCA this sets the maximum crew aboard to 12 for offshore voyaging); along with a new ship’s EPIRB and eight personal EPIRBS. Life jackets for eight, tested serviceable at the end of 2015, and tethers are aboard. A full suite of MOB recovery equipment is aboard (slings, nets, rescue triangle). New thermal suits for eight were purchased in 2015.

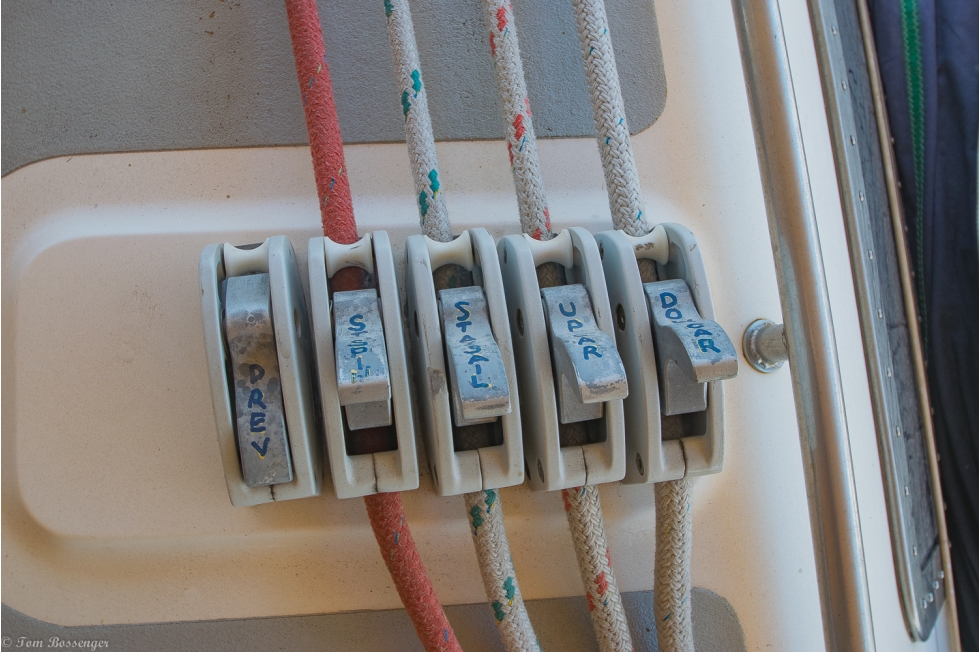

Furler reefing on both her jib stays and hayracks on the boom have made sail changes easier. IRONBARQUE carries sails to permit either a blade jib and full mainsail; or a full mainsail with staysail and yankee jibs. All equipment, including the massive spinnaker and dual carbon fiber spinnaker poles, are aboard for running downwind though short-handed crews will find poling out the blade jib wing to wing with the main is more manageable. For foul weather, a storm staysail and storm triangle main on a separate mast track are aboard. Powered winches have been added to support the halyards (center line forward) and the blade jib sheets (port and starboard aft).

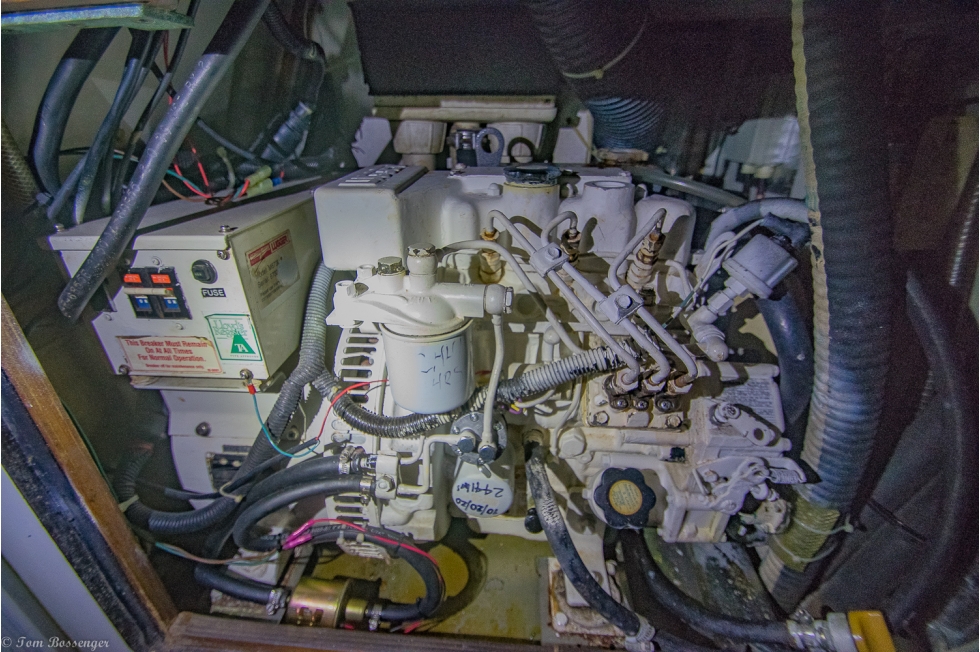

The main engine, a Perkins M130C was totally rebuilt in 2015 as was the gear box. The throttle/gear cable to the wheel control was replaced in 2016. The Northern lights generator received a new exhaust knee and injectors in 2015. Both diesels are in excellent condition. The engine room has been fitted with an inert gas fire suppression system.

To improve long range fuel consumption, wind and solar electricity generation capability was added. The two AIR-X wind generators were serviced in 2016 with blades, new bearings and a fresh coating with white powder coat paint.

A custom stainless steel stern arch was added in 2009.

Construction Detail

- Hull - 50A mild steel

- Keel - Steel fin. Lead bulb

- Deck and Coamings - 316 stainless steel with non-slip TBS pads

- Coachroof - GRPBalsa Sandwich

History of the Challenge 72 Yachts

12 yachts were built for the 2000/01 BT Global Challenge and all of them successfully completed the 10 month westabout circumnavigation.

During the autumn of 2003 they underwent a series of detailed surveys and inspections. Whist the yachts and all their systems/equipment were found to be in exceptionally good condition, they underwent a major refit. The 12 yachts set off on their second circumnavigation in October 2004 and again all of them successfully completed the 10 month westabout circumnavigation.

The refit amounted to a virtual rebuild with all the systems and equipment being replaced. This included new plumbing, wiring, engine, generator, batteries, pumps, deck equipment, steering gear, mast, spars, rigging and sails. Exactly the same amount of equipment and components were supplied to the “original yachts” for their refit as for the new yacht build. Shot blasting and repainting further ensured that the yachts were returned to 'as new condition'. As a result it was virtually impossible to identify from which build period each yacht originated. The specification was identical to the newly built yachts, as was their structural and cosmetic condition.

Accomodation

The Challenge Fleet were designed to be self-sufficient and have adequate stowage to enable them to stay at sea for up to 55 days in any part of any Ocean. The Challenge races have illustrated the yacht's ability to do this with a surprising degree of comfort, in absolute safety. A multitude of handrails & pillars allows safe movement below decks. The saloon is light, airy and dry with good ventilation, which enables food to be prepared in tropical or Southern Ocean conditions in the galley. The comfortable seating area has fabric upholstery.

IRONBARQUE offers at least 6’6” of head room throughout its length; though one does have to duck going through the water tight doors and open bulkheads.

The original eighteen berths were situated in 3 cabins with pipe births. Examples of the fittings and birth cloths have been retained.

Water Tight Compartments:

The Challenge design is divided into six water tight compartments:

- The forward collision chamber – entry is from the sail locker via a bolted steel plate over in the aft bulkhead of the chamber.

- The sail locker – divided from the forward cabins by a dogable water-tight door. Egress from the sail locker is via the large forward mid-line hatch.

- The forward cabins – divided from the main cabin/galley by a dogable water-tight door. Egress from the forward cabins is possible only via the sail locker or galley.

- The main cabin/galley – divided from the aft cabins by two a dogable water-tight doors; port and starboard. Egress from the main cabin/galley is via the main companionway hatch.

- The aft cabins – limited by the main aft bulkhead. Egress from the aft cabins is either via the main cabin or the aft midline- hatch.

- The aft collision chamber – entry is only via two bulkhead mounted Lewmar hatches; one each accessed by the port and starboard bunks.

Accommodation from Forward to Aft:

The aft cabin has port and starboard fixed bunks with a storage shelf above each. In addition there are six large capacity in built storage boxes.

In the mid aft cabin, on the port side, there is one outboard fixed birth with a storage shelf above it. Under this birth is an Engel MT80 DC refrigerator/freezer and a storage space for bulky items. Aft of the birth are 12 storage boxes mounted in two vertical stacks.

Inboard the births that were midline have been replaced by a cushioned bench as a relaxation/reading spaced. Access to the engine bay/gearbox is under this bench.

In the aft mid cabin, on the starboard side, there is one outboard fixed birth with a storage shelf above it. Underneath this bunk is storage space for the spinnaker and other bulky items. Aft of the birth are 12 storage boxes mounted in two vertical stacks.

Inboard there are one fixed and one pipe birth in the midline. Access to the engine bay/gearbox is under the lower bunk. If carried, the solar panels can be stored in this space. There are four access ports to the aft bilges on both the starboard and port sides. The storage space is cavernous. Under floor springers permit tie downs so that stored items are secure.

In addition to the aft hatch, there are three dogable ports facing inboard into the crew wells on both the port and starboard sides for ventilation. Fly screens can be fitted/are available for each of these. In addition, DC fans have been mounted to ensure air circulation. These can be operated to support air circulation or with either heating or air conditioning activated.

The main cabin/galley offer seating accommodation and a navigation seat that can double as a watch birth. Under the sole there is cavernous bilge storage. Painted wooden slats have been fitted to keep stored items from contact with the bilge floor – these are demountable for cleaning and to inspect the bilge hull plating.

There are massive amounts of above the sole storage in cupboards in the galley/main cabin.

Fids are fitted to all shelves. Under and behind the cushions of the main settee there is storage for spare parts and service kits for the engines, winches and deck hardware.

There are two cabins forward. The port cabin is fitted with two fixed births and a stack of four storage boxes. The starboard cabin is fitted with two wider storage shelves that can be used for sail storage or as bunks. Both cabins offer access ports to the outboard forward bilges. Access to the midline bilges is available under the sole.

All births are fitted with lee cloths and reading lights. All cabins have Dorade vents.

Sail room:

The sail room is situated aft of the collision bulkhead and the full inventory of sails can be stowed here together with all the warps, fenders, sheets and guys. The main & kedge anchors together with their associated chain and warps are also securely stowed in this compartment. A central passageway runs aft from the sail room to the deckhouse.

Head & Shower Compartments:

Head/shower compartments are situated on either side, each with Raritan PE Manual heads, washbasin and shower (new in 2016). The heads can be directed to a 40gallon black water holding tank or piped overboard.

Chartroom/Deckhouse:

The navigation & communication equipment is situated around the full size chart table, facing aft behind the main saloon.

Drying/Oilskin Room:

With hanging/drying space for a full complement of foul weather gear, Mikuni Diesel hater (new 2009), watermaker (new 2016) and fuel day tank.

Galley:

A gimbaled 5-burner domestic size Calor gas hob is mounted in a custom-made stainless steel housing. Substantial fiddles allow safe preparation of food at sea in virtually any conditions. A separate Calor gas oven is mounted at the forward end of the proper sea going galley. Five course Christmas meals complete with fresh baked bread and pudding have been prepared in this galley.

The galley sink is a single piece custom stainless steel unit (new 2015) with teak cutting boards to fit over the sinks. Two custom knife and gadget drawers have been fitted outboard.

- New galley fans were fitted 2015.

- The galley has an Engel DC MT17 “day use” refrigerator/freezer unit.

Hot Water System:

IRONBARQUE is fitted with a Cleghorn electrical hot water heater (CWB64-HT3 64 litre Horizontal Water Storage Heater with a CW239 11" Immersion Heater). Pressurized hot water is available in the galley and both heads.

Refrigeration:

The current owners put in two Engel DC powered refrigerator freezers. The smaller MT17 unit (new in 2008 and a veteran of 25,000 sea miles) is lashed down in the seating position that is the midline/forward corner of the main saloon settee (the seat that no one wants to have). It provided cold drinks and preservation of opened perishable foods.

The MT80 unit is the largest portable unit that can be brought aboard IRONBARQUE (the aft hatch was modified to permit it to be brought aboard and removed if require). It can freeze sufficient prepared “meat” portions (meat sauce, chilli, apricot chicken etc) to support a month at sea for a family of six with space to claim the occasion catch of fresh fish. The decision to use portable units was made to avoid the long term service nightmares associated with in built freezer units. This decision can be easily reversed by a new owner using the under bunk spaces in the mid aft cabins.

Navigation and Electronics

- Ships Onboard Instrumentation - Brookes & Gatehouse Hydra System with KVH gyro stabilising compass, four 20/20's, two full function displays and two 3600 wind direction. New mast wiring 2010.

- Suunto pedestal compass 2010.

- GPS - LYCA MX400 & B&G 12 PLUS.

- Satellite Communications - Thrane & Thrane Inmarsat Standard C Terminal TT3020C.

- VHF - Shipmate RS8400.

- Hand Held VHF - 2x ICOM Hand Held VHF. 1 x Raymarine Hand Held VHF.

- GMDSS - ICS Electronics Ltd.

- 2 x Conrod GMDSS/SSB whip aerial.

- SSB - ICOM 150 watt HF radio ICM710 GMDSS.

- Radar - Furuno radar (2009).

- Battery Monitoring Equipment.

- Satellite Communications equipment –fixed station IRIDIUM with high efficiency antenna for voice and email.

- Computers – Three identical DELL XPS M1530 laptop computers that are “hot swappable” to run the TRANSAS navigation software (2010). 2 mounted LCD displays (2010). Licenses provided for TRANSAS (World portfolio and AIS 2008), PCSat. Dell Latitude XT2 rugged laptop for wireless repeater at the helm (2010) – this unit meets military (MIL-STD-810G) and IP54 (Ingress Protection) standards for operation in challenging conditions.

- Stereo - Sony CD/Radio with internal and external speakers 2008. In settee speakers and deck speakers fitted.

- 36” plasma TV with own 1kw inverter on forward bulkhead.

- Internal TPC-IP wireless network with forward and aft wireless repeaters (it is a steel boat) and 4 TB network storage.

- Fixed and hand held.

Deck

The deck equipment was selected for its efficiency, robustness and ease of maintenance. All the equipment used fully justified its selection and remains in good condition.

Deck Equipment:

- Hatches & portholes - Lewmar Ltd & Nemo. Large main sailing handling hatch is new 2016.

- Steering Gear- Edson USA. New in 2011 with spare chain, wire and turning hardware carried in the inventory.

- Winches & Deck Equipment - Harken USA. The main centre-line halyard winch and the port and starboard jib winches are powered.

- Pulpit, pushpits, stanchions, handrails etc - Hercules CSMD of Dartmouth and Baja Naval of Ensenada.

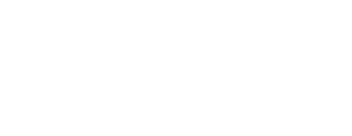

- Blocks, jammers etc - Designed by Roger Scammell, Manufactured by Hercules CSMD. The port, starboard and main sets of jammers/wedge blocks were replaced in 2009.

- Reenforced stainless steel custom Sampson posts (three per side).

- Port and starboard Lewmar anchor winches.

- Main anchors are CQR and Bruce anchors (100 lbs). 2x330' chain high test chain plus an additional 150' of 1” nylon rode. Each anchor is provided with a nylon snubbing bridal with tethers that terminate in spliced eyes to slip on the bow Sampson posts.

- The stern/kedge anchor is an aluminum Fortress 30lb anchor on a 150' nylon rode.

- Custom Jordan Series Drogue by Ace Sailmakers.

Mechanical

- Main Engine – Perkins M130C Sabre Engines Ltd.

- Generator - Northern Lights M673L 5.5Kw.

- Engine & Generator Exhaust System - Halyard Marine Ltd.

- Watermaker – New.

- Propeller - 3 bladed (Bruntons Propellers Ltd). A spare fixed propeller with fitting key is carried in a dedicated storage box under the stb sole aft.

- Accommodation Heater - Mikuni diesel heater with 7 outlets with fan blowers; replaced exhaust pipe plus new insulation (2013).

- Radiator heating is provided in all cabin areas with fan assistance.

Electrical

- Original Mastervolt battery chargers replaced 2010/2016 with higher capacity MaxSine units.

- New MaxSine inverter and electrical hot water fitting in 2010.

- Batteries – 6 x 8D batteries for the house bank (2020). Additional 12 x 4D batteries fitted (2020) to support air conditioners. 3 12v batteries in the saillocker to support the bow thruster.

- Solar panels and two wind turbines (2020)

- Switch Panels - Energy Solutions electrical panels with Carling circuit breakers, ammeters and voltmeters.

- Electrical Standards - Bureau Veritas approved cabling and components.

- Inverter – MaxSine interver to support how water and chargers (new 2012 and 2014)

- Shore power with isolation transformer.

- 4 x 12 v “cigarette lighter” type outlets fitted to the main setter.

- 1 kv inverter in the forward lower storage cupboard to support the TV.

Sails

- Dacron sails - 2 x Vectran mainsail (new 2004) – fully battened with Bainbridge Sailman Batten system, Vectran blade jib, No 1 Yankee, No 2 Yankee & Staysail, Dacron Storm staysail & Storm Trysail.

- Spinnaker – 2000 1.5oz unbranded; asymmetric spinnaker (with top snuffer).

Watch Video:

Ironbarque Video Tour

location:

Presented by :